About the Department

Meenakshi Sundararajan Engineering College inaugurated the Department of Mechanical Engineering in the academic year 2011-12 and is affiliated to Anna University. Under the erudite leadership of Dr. S. SanthanaKrishnan , Head of the department along with the efficient faculty members and excellent students, the department has won laurels to the college. The department has well qualified faculties with excellent teaching, training and industrial experience. It has state-of-the-art laboratories catering to academic, consultancy and research requirements. The department’s endeavor is to develop its students to be `industry ready` when they graduate. Students of mechanical engineering department gain industrial exposure and are prepared to face future challenges by carrying out their Final Year Projects work in various PSU/Private sectors as per their field of interest relevant to their program. The department has memorandum of understanding with varies Institutions, Industries and Research organizations for collaborative research and development work. There is huge potential in the department for Consultancy as well as Technology and Product incubation. The Department takes pride in achievements of its alumni, who have shined in various walks of life throughout the world.

Accredited by the National Board of Accreditation for 3 years from the Academic Years 2023-24 to 2025-26 i.e. upto 30.06.2026 ![]()

(Previously from the Academic Years 2020-21 to 2022-23)

Vision of the Department

To develop creative mechanical engineers by providing quality education, research and ethical values.

Mission of the Department

Program Educational Objectives Statements

Program Specific Outcomes

Program Outcomes

The graduates in Mechanical Engineering will:

Course Outcomes

Click for 2017 Regulation

INFRASTRUCTURE

The vision of our institution is to provide facilities for students to learn the skills needed to become an industry ready mechanical engineer. Towards realization of this vision, we have established manufacturing laboratories, with an array of conventional machines like lathe, planner, shaper, slotter, milling machine etc. as well as modern method machines like CNC lathes, CNC machining center, Electric Discharge machines, Wire Cut EDM and Injection moulding machines which are having a capacity to undertake the industrial work load from the leading industries like Lucas TVS etc., We also provide support services for manufacturing press tools, jigs, fixtures etc. A state of the art metrology laboratory is being put in place for training our students in modern methods of design, manufacture, Inspection and testing.

We have established a computer laboratory in the Mechanical Engineering department with a bank of 72 High configuration computers equipped with licensed software’s such as CRE-O, Auto Cad, MSC Nastran and ADAMs Multi-body dynamics simulation software. This facility enables our students to learn to design components, to carry out 3D modeling, and to undertake projects in the areas of product design, development, and manufacturing. We have left no stone unturned with the intention of ensuring our students who graduate are highly competent Mechanical Engineers contributing in Nation Building Activities.

Department of Mechanical Engineering Laboratory Facilities

|

NAME OF LABORATORY |

LABORATORY EQUIPMENT’S |

|

Engineering Practices Laboratory

|

1.Central lathes 2. Welding 3.Carpentry 4. Plumbing 5. Sheet metal |

|

Manufacturing Technology-I

|

1.Centre Lathes 2.Horizontal Milling Machine 3. Vertical Milling Machine 4. Shaper 5.Injection moulding machine(For industrial consultancy work) |

|

Fluid Mechanics And Machinery Laboratory

|

1.Orifice meter setup 2.Venturi meter setup 3. Rotameter setup 4. Pipe Flow analysis setup 5. Centrifugal pump/submergible pump setup 6. Reciprocating pump setup 7. Gear pump setup 8. Pelton wheel setup 9. Francis turbine setup 10. Kaplan turbine setup |

|

Thermal Engineering Laboratory –I

|

1.I.C Engine – 2 stroke and 4 stroke model 2. Apparatus for Flash and Fire Point 3 .4-stroke Diesel Engine with mechanical loading 4 .4-stroke Diesel Engine with hydraulic loading. 5. 4-stroke Diesel Engine with electrical loading 6. Multi-cylinder Petrol Engine 7. Single cylinder Petrol Engine 8. Data Acquisition system 9. Steam Boiler with turbine setup |

|

Manufacturing Technology Laboratory–II

|

1.Turret & Capstan Lathes 2. Horizontal Milling Machine 3 .Vertical Milling Machine 4. Surface Grinding Machine 5. Cylindrical Grinding Machine 6. Radial Drilling Machine 7. lathe Tool Dynamometer 8. Milling Tool Dynamometer 9. Gear Hobbing Machine 10. Tool Makers Microscope 11. CNC Lathe (For industrial consultancy work) 12. CNC Milling machine(For industrial consultancy work) 13. Gear Shaping machine 14. Center-less grinding machine (For industrial consultancy work) 15. Tool and cutter grinder |

|

Strength of Materials Laboratory

|

1.Universal Tensile Testing machine 2 .Torsion Testing Machine 3 Impact Testing Machine 4. Brinell Hardness Testing Machine 5. Rockwell Hardness Testing Machine 6. Spring Testing Machine for tensile and compressive loads 7. Metallurgical Microscopes and Micro-structure Polishing machine 8. Muffle Furnace |

|

Dynamics Laboratory

|

1.Cam follower setup 2. Motorized gyroscope. 3. Governor apparatus 4. Whirling of shaft apparatus 5. Dynamic balancing machine. 6. Two rotor vibration setup 7. Spring mass vibration system. 8. Torsional Vibration of single rotor system setup 9.Gear Models 10.Kinematic Models to study various mechanisms 11.Turn table apparatus 12.Transverse vibration setup of Free-Free beam 13. Forced vibration setup for cantilever beam. 14. Balancing of Rotating masses 15. Balancing of reciprocating masses |

|

Thermal Engineering Laboratory-II

|

1.Guarded plate apparatus 2. Lagged pipe apparatus 3.Natural convection-vertical cylinder apparatus 4. Forced convection inside tube apparatus 5. Composite wall apparatus 6. Thermal conductivity of insulating powder apparatus 7. Pin-fin apparatus 8. Stefan-Boltzmann apparatus 9. Emissivity measurement apparatus 10.Parallel/counter flow heat exchanger apparatus 11. Single/two stage reciprocating air compressor 12. Refrigeration test rig 13. Air-conditioning test rig 14. HC Refrigeration System 15. Fluidized Bed Cooling Tower |

|

Metrology and Measurements Laboratory

|

1. Micrometer 2. Vernier Caliper 3. Vernier Height Gauge 4. Vernier depth Gauge 5. Slip Gauge Set 6 .Gear Tooth Vernier 7. Sine Bar 8 .Floating Carriage Micrometer 9. Profile Projector / Tool Makers Microscope 10. Mechanical / Electrical / Pneumatic Comparator 11. Autocollimator 12 .Temperature Measuring Setup 13. Force Measuring Setup 14.Torque Measuring Setup 15.Coordinate measuring machine 16.Surface finish measuring equipment 17.Bore gauge 18. Telescope gauge 19. Faro CMM |

|

C.A.D. / C.A.M. Laboratory

|

1.Computers (72nos.) 2.Softwares Ø Auto CAD, Ø Cre-O Parametric Ø CAPsTurn Ø CAPsMill Ø CNC programming tool path simulation for FANUC controller 3. CNC Turning Centre 4. Vertical CNC Milling machine |

|

Simulation and Analysis Laboratory

|

1.Computers (72nos.) 2.Softwares MSC.Nastran, Patran 3.ADAM 4.MatLab |

|

Mechatronics Laboratory

|

1.Controls/ PLC Control each 2 Basic Hydraulic Trainer Kit 3. Hydraulics and Pneumatics Systems Simulation Software (Lab View) 4.8051 – Micro controller kit with stepper motor and drive circuit sets 5.Image processing system with hardware & software 6. 3D-Printer. 7. Basic Pneumatic training kit. |

Professional Society Association;

SAE STUDENT CHAPTER

SAEINDIA is India's leading resource for mobility technology. Department of mechanical engineering of Meenakshi Sundararajan Engineering College, has formed the SAE India Collegiate Club during the year 2014. Students are enrolled to become membership and encourage to participate in all engineering event organized by SAE India. The student chapter organizes various events such as guest lectures, industrial visits, and competitions etc. for the SAE student members. The student members actively participate in all the events organized by SAE India like BAJA, Bi-Cycle Design Challenge and etc.

The SAE India magazines key in on hot topics about ground vehicle and aircraft developments, providing members with a valuable resource to help keep pace with rapidly changing technology in the mobility industry. One hard copy of each is also sent to one of the faculty Advisers in kept in department library for student’s reference. Students are taken to the leading automotive vehicle and component manufactories companies through their collegiate clubs based on request to these companies (however, it is no mandatory for these companies to accept the request all the time) these visits give first-hand information about the industrial environment and also attend technical seminars delivered by industry professionals. Student member participate in various technical event and attend technical seminar conducted by SAE INDIA.

SOCIETY OF AUTOMOTIVE ENGINEERS INDIA (SAEINDIA) COLLEGIATE CLUB MEMBERSHIP DETAILS

|

Academic Year |

II Year |

III Year |

IV Year |

Total Number of Student Membership |

|

2019-2020 |

45 |

33 |

57 |

135 |

|

2018-2019 |

Nil |

57 |

61 |

118 |

|

2017-2018 |

57 |

61 |

60 |

178 |

|

2016-2017 |

59 |

59 |

56 |

174 |

SAE ACTIVITIES

|

Sl.No |

Name of the activity |

Number of Co –curricular Activities and Extracurricular Activities |

|||

|

2019-2020 |

2018-2019 |

2017-2018 |

2016-2017 |

||

|

1 |

Number Of Events Organized |

3 |

1 |

1 |

- |

|

2 |

Number Of Events Participated Outside |

1 |

1 |

1 |

- |

DETAILS OF EVENT ORGANIZED IN CAMPUS BY SAE COLLEGIATE CLUB in Academic year 2019-2020

|

Academic year 2019-2020 |

|||||||

|

S NO |

EVENT |

DATE |

DURATION |

TOPIC |

RESOURCE PERSON |

PARTICIPANTS S |

|

|

BATCH |

Yr. |

||||||

|

1 |

SAE-Technical Seminar |

01-04-2020 |

3 Hrs |

Campus to Corporate Dialogue,Overview of Automobile Sector, Processes involved in Manufacturing aggregate parts, Career Mapping |

Mr. N. Shanmugasundaram, Mr. Kannan N Krishnan, Mr. R. Shreedhar Daimler India Commercial Vehicles Pvt, Ltd. |

2016-2020, 2017-2021, 2018-2022 |

II,III,IV |

|

2 |

SAE-Workshop |

22-01-2020 |

3 Hrs |

Work on Solidworks Design to Manufacturing |

Gowtham, Application Engineer, SIMTEK |

2017-2021 |

III |

|

3 |

Akshobya- SAE Technical Seminar |

24-01-2020 |

2 Hrs |

E-Mobility in Off road application |

Mr. Ravindaran, Principal Member , TAFE |

2016-2020, 2017-2021, 2018-2022 |

II,III,IV |

|

2 Hrs |

Electric Mobility |

Mr. M. Prasad, President, Agnito insights |

|||||

|

2 Hrs |

Electric Mobility- Vehicles and future |

Mr. P. Nageshwar Roa, Mentor & Design Consultant, (Ex), TAFE. |

|||||

|

2 Hrs |

Electric Mobility- Design Overview |

Mr. S. Prabhakaran, CADD CENTER |

|||||

DETAILS OF EVENT ORGANIZED IN CAMPUS BY SAE COLLEGIATE CLUB in Academic year 2018-2019

|

Academic year 2018-2019 |

|||||||

|

S NO |

EVENT |

DATE |

DURATION |

TOPIC |

RESOURCE PERSON |

PARTICIPANTS S |

|

|

BATCH |

Yr. |

||||||

|

1 |

Technical Seminar SAE |

19.01.2019 |

4 Hours |

Catalytic Convertors |

D.Srivallaban,Human Resource Manager, BASF Catalysts India Private Limited |

2016-2020, 2017-2021 |

III & II |

DETAILS OF EVENT ORGANIZED IN CAMPUS BY SAE COLLEGIATE CLUB in Academic year 2017-2018

|

Academic year 2018-2019 |

|||||||

|

S NO |

EVENT |

DATE |

DURATION |

TOPIC |

RESOURCE PERSON |

PARTICIPANTS S |

|

|

BATCH |

Yr. |

||||||

|

1 |

Engineers' Day SAE- Techniclal Seminar |

16.08.2017 |

3 Hrs |

Electronics Controls in Mechanical Systems |

Dr. Subramanian Sundaresh |

2014-2018, 2015-2019, 2016-2020 |

IV, III II |

|

3 Hrs |

Control Systems in Nuclear Engineering |

Ms. Jalaja Madan Mohan |

|||||

SAE INTER-COLLEGE EVENT

|

S NO |

Academic Year |

DATE |

Event |

Venue |

|

1 |

2019-2020 |

8th,& 9th of Feb 2019

|

Work Shop on “Bi-Cycle Design Challenge 2020” |

Rajalakshmi Enginering College, Chennai |

|

2 |

2018-2029 |

14th , 15th , and 16th of July 2018 |

Virtual BAJA SAE |

Chitkara University, Punjab |

|

3 |

2017-2018 |

13th and 14th Of July 2017 |

Virtual BAJA SAE |

Chitkara University, Punjab |

|

4 |

10th and 9th Of Sept 2017 |

Workshop Computational Fluid Dynamics Using Openfoam |

Chennai |

|

|

4 |

2016-2017 |

Feb 4th and 5th

|

Workshop on Automobile Engines |

Chennai |

Co-Curricular Actiities

INDUSTRIAL VISIT

|

Academic year 2019-2020 |

|||||||

|

Batch |

Year |

Sem |

Company |

Place |

Field /Area Of Visit |

Date |

No Of Students |

|

2018-2022 |

2 |

III |

Abi Showatech |

Shollingur |

Turbo Charger & Brake Components Manufacturing Unit |

20-Sep-19 |

59 |

|

2017-2021 |

3 |

V |

EAsun MR Tap Changers (P) Ltd |

Pondicherry |

Transformer & tap Changers manufacturing unit |

3-Aug-19 |

62 |

|

2016-2020 |

4 |

VII |

Ashok Layland Unit 1 |

Hosur |

Bus Body manufacturing Unit |

2-Aug-19 |

63 |

|

Academic year 2018-2019 |

|||||||

|

2016-2020 |

3 |

V |

Abi Showatech |

Shollingur |

Turbo Charger & Brake Components Manufacturing Unit |

20-Jul-18 |

63 |

|

2015-2019 |

4 |

VII |

TVS Motors |

Hosur |

Two Wheel Assembly Unit |

8-Oct-18 |

71 |

|

2017-2021 |

2 |

IV |

Ennore Power Plant |

Ennore |

Thermal power Plant |

5-Jan-19 |

62 |

|

2016-2020 |

3 |

VI |

EAsun MR Tap Changers (P) Ltd |

Pondicherry |

Transformer & tap Changers manufacturing unit |

9-Feb-19 |

62 |

|

Academic year 2017-2018 |

|||||||

|

2015-2019 |

3 |

V |

EAsun MR Tap Changers (P) Ltd |

Thiruninravur |

Transformer & tap Changers manufacturing unit |

21-Sep-17 |

71 |

|

2014-2018 |

4 |

VII |

Ennore Power Plant |

Ennore |

Thermal power Plant |

|

|

|

2016-2020 |

2 |

IV |

Ashok Leyland |

Ennore |

Bus Body manufacturing Unit |

14-Dec-17 |

62 |

|

2016-2020 |

2 |

IV |

Neyveli Lignite Corporation |

Neyveli |

Thermal power Plant |

9-Mar-18 |

62 |

|

2015-2020 |

3 |

VI |

North Chennai Power Plant |

Athipatttu |

Thermal power Plant |

24-Feb-18 |

71 |

|

2015-2019 |

3 |

VI |

Bharath Heavy Electricals Ltd. |

Ranipet |

Boilers Auxillieries manufacturing Unit |

28-Feb-18 |

71 |

|

Academic year 2016-2017 |

|||||||

|

2014-2018 |

3 |

V |

Ashok Leyland |

Hosur |

Bus Body manufacturing Unit |

10-Sep-16 |

66 |

|

2013-2017 |

4 |

VII |

BHAVINI, Kalpakkam |

Kalpakkam |

Nuclear Power Station |

4-Mar-16 |

64 |

|

2015-2019 |

2 |

IV |

Abi Showatech |

Shollingur |

Turbo Charger & Brake Components Manufacturing Unit |

3-Mar-17 |

71 |

|

2015-2019 |

2 |

IV |

Neyveli Lignite Corporation |

Neyveli |

Thermal power Plant |

20-Mar-17 |

71 |

|

2014-2018 |

3 |

VI |

EID PARRY India Pvt. Ltd |

Cuddalor |

Sugar Factory |

|

66 |

Academics

The Department of mechanical engineering is educating students who are destined for excellence. The Department started the under graduate program in the year 2001 with an intake of 60 students. The first batch of the department has achieved cent percent university result, with one university Gold medalist and four university ranks.

From inception, among the four batches that have passed out successfully, and the department has secured 12 University ranks till 2019.

University Rank Holders List

|

Reg.No |

Student Name |

Rank Position |

Batch |

|

311511114022 |

Karthik Hari .D |

Gold Medal |

2011-2015 |

|

311511114052 |

Vignesh .K |

9 |

|

|

311511114051 |

Vignesh .B |

22 |

|

|

311511114014 |

Dharshan .P |

48 |

|

|

311511114039 |

Shashank .M |

50 |

|

|

311512114014 |

Elanchezhiyan .S |

7 |

2012-2016 |

|

311513114029 |

Madhanagopal .T |

9 |

2013-2017 |

|

311514114028 |

Manoj. A |

23 |

2014-2018 |

|

311514114035 |

Prassanna Kumaran G.R |

31 |

|

|

311514114045 |

Sathish. P |

33 |

|

|

311515114002 |

Adithya Venkatesh |

14 |

2015-2019 |

|

311515114028 |

Maheswaran.A |

21 |

|

S.NO |

Batch |

Number of University Ranks |

|

1 |

2011-2015 |

5 |

|

2 |

2012-2016 |

1 |

|

3 |

2013-2017 |

1 |

|

4 |

2014-2018 |

3 |

|

5 |

2015-2019 |

2 |

Percentage of Graduation

|

Year of Admission |

2012-13 |

2013-14 |

2014-15 |

2015-16 |

|

Year of Completion |

2015-16 |

2016-17 |

2017-18 |

2018-19 |

|

No. of Students Admitted |

70 |

68 |

69 |

71 |

|

No. of Students Appeared for Exam |

70 |

68 |

69 |

71 |

|

No. of Students Successfully Completed in 4 Years |

64 |

63 |

64 |

66 |

|

Percentage of Students Successfully Completed in 4 Years |

93 |

93 |

93 |

91 |

Psychrometric|video 19|cooling and Dehumidification|UNIT V GAS MIXTURES AND PSYCHROMETRY

Links of You tube Video Lecture by our department faculty

EVENTS

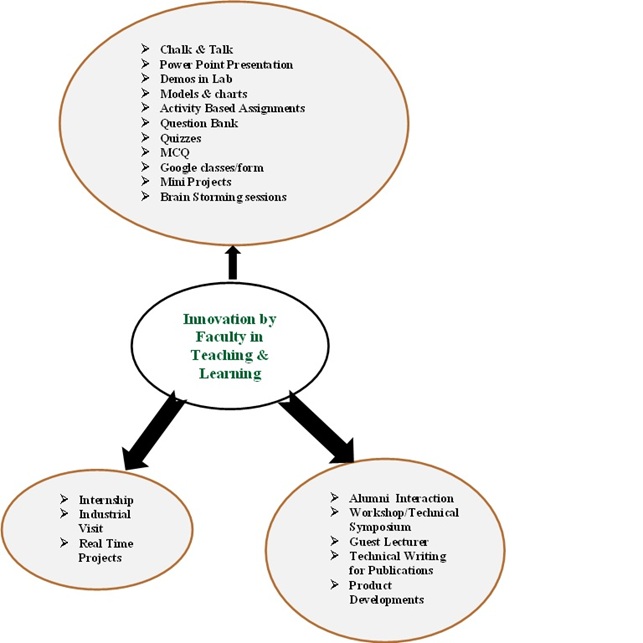

The department maintains a very vibrant academic atmosphere through varies academic initiatives.

E-Cube (Enrichment, Enhancement and Empowerment) Programme

Various activities are organized through the E-cube event during every academic year for the students. Every individual student participates in paper presentation on a technical topic of their interest. The third and final year student had to present a mini-project plan. Eminent people are invited from the core industries to judge the student competence and to expose them to real life challenges. The projects are analyzed to industrial standards and are given valuable assistance for implementation. The students are also guided for resume writing and a mock interview is conducted by officials invited from core companies. The event is well appreciated by our alumni as it enabled the students to enrich, enhance and empower themselves to be ready for the future industry.

AKSHOBYA – ONE DAY TECHANICAL SEMINAR

The mechanical engineering one day technical seminar provides an opportunity to all students to increase the depth of his scientific knowledge. It also offers an ideal platform to initiate discussion on recent trend and development in the industry and also topic on interdisciplinary work cutting across boundaries. There is a regular stream of visitors to the department from varies institution, core industries and research organizations, resulting in industrial collaboration and interactive seminar for the benefit of students.

Engineer’s Day

The management, staff and students celebrate Engineer’s Day every year as a tribute to the greatest Indian Engineer Bharat Ratna Mokshagundam Visvesvaraya. “Role of Engineer’s in the developing India is the theme of Engineer’s Day. After the floral tribute, the department Newsletter “SPARKS” and project summary is release by the distinguished chief guest. Eminent research scholars are invited to present their research work and discuss about recent developments in industries.

Symposium

YANTRA is the annual national level technical symposium of the department of Mechanical Engineering. It provides a stage for the aspiring minds to establish their talents and showcase it to the right audience. A range of challenging events draws enthusiastic participants, adding luster to the show.

Conference

Conference gives the opportunity to learn and share the latest research findings by the researchers. It serves as platform to publish articles on research topics. Resource persons invited are experts from abroad and from various R&D institutions. Conferences organized by the department during the academic year are listed below,

INTERNATIONAL MULTI-DISCIPLINARY CONFERENCE ON SOLAR ENERGY – 2012

Keynote Speaker

NATIONAL CONFERENCE ON EMERGING TRENDS IN MECHANICAL ENGINEERING - 2017

Chief Guest

Dr. Anil Kumar Sharma, Senior Research Scientific Officer, Safety Research Laboratory, Reactor Technology Group, (IGCAR), Department of Atomic Energy, and Faculty Member (Engineering Sciences), HBNI, Mumbai.

NATIONAL CONFERENCE ON RECENT TRENDS IN WELDING TECHNOLOGY – WELDTECH 2018

Chief Guest

R Easwaran, Retired General Manager- In Charge (Quality, WRI and Labs), BHEL, Tiruchirappalli.

Keynote talk

|

Sl.No |

Name of the activity |

Number of Co –curricular Activities and Extracurricular Activities |

|||

|

2019-2020 |

2018-2019 |

2017-2018 |

2016-2017 |

||

|

1 |

Technical Seminars |

1 |

1 |

1 |

1 |

|

2 |

Workshop |

1 |

5 |

- |

- |

|

3 |

Industrial visit |

3 |

4 |

6 |

5 |

|

4 |

Intern-ship |

13 |

11 |

75 |

24 |

|

5 |

In-plant training |

41 |

125 |

23 |

11 |

|

6 |

Guest lectures |

2 |

- |

3 |

1 |

|

7 |

Conferences |

Planned |

1 |

1 |

1 |

|

8 |

Students Paper/ Journal Publications |

18 |

1 |

1 |

1 |

|

9 |

Symposiums |

1 |

1 |

1 |

1 |

|

10 |

Enrichment, Enhancement and Empowerment (E-Cube) |

1 |

1 |

1 |

1 |

|

11 |

Value-added courses (Japanese Language) |

45 |

59 |

62 |

56 |

|

12 |

Carrier Guidance Program |

1 |

5 |

2 |

1 |

|

13 |

NPTEL Certification |

16 |

7 |

- |

- |

|

14 |

SAE Technical Seminar |

2 |

1 |

1 |

- |

|

15 |

SAE Inter-College Event |

1 |

1 |

1 |

- |

|

16 |

Alumini Talk |

1 |

- |

1 |

- |

|

17 |

Yearly News Letter |

- |

1 |

1 |

1 |

|

18 |

Annual Magazine |

- |

1 |

1 |

1 |

|

19 |

Engineers' Day |

1 |

1 |

1 |

- |

|

20 |

Pre Placement training |

1 |

1 |

1 |

1 |

|

21 |

NSS Camps and YRC Cleanliness Drives |

|

6 |

5 |

5 |

|

22 |

Annual Inter-Faculty and Students Sports Competitions |

1 |

1 |

1 |

1 |

|

23 |

Celebration of National Days |

1 |

2 |

2 |

2 |

|

24 |

College Day |

Planned |

1 |

1 |

1 |

|

25 |

Graduation Day |

Planned |

1 |

1 |

1 |

Associations

Department Achievements

Faculty Achievements

Patents Applied:

Dr. V S Raghunathan and Lokeswaran K (Batch 2011-2015) of MSEC have applied for a patent on “NOVEL SEP-ARATION ROUTE FOR METAL-SLAG REACTION PRODUCT” 2016

Faculty Journals Published:

Conference Attended:

Student Achievement and Event Participation:

Topic: Automotive Engines Venue: SAEINDIA Southern Section

Speaker: Dr. M. SenthilKumar, Professor, Anna University.

Paper Presented by Students:

Student Journal Publications:

SAEINDIA Event:

25 students from Mechanical made the attempt by participating in the prestigious event Virtual BAJA 2017 at Chitkara University, Punjab conducted on 14th, 15th and 16th of July 2017.

|

S.No |

Name of the faculty |

Qualification |

Designation |

Areas of Interest |

|

1 |

Dr. S. V. Saravanan |

B.E., M.E., Ph.D., M.B.A., D.Litt. |

Principal and Professor |

IC Engines, Energy Management |

|

2 |

Mr. N. Sreekanth |

B.E., M.S |

Associate Professor |

Manufacturing |

|

3 |

Dr. S. SanthanaKrishnan |

M.E.,Ph.D |

HoD & Associate Professor |

Heat and Mass transfer, Thermal Engineering, Gas Dynamics Jet Propulsion, Alternate Fuel |

|

4 |

Mr. K. Iyyanar |

M.E |

Assistant Professor |

Material science & CAM |

|

5 |

Dr. S. Kamatchi Sankaran |

M.E.,Ph.D.,M.B.A |

Professor |

Thermal Engineering, Material Science |

|

6 |

Mr. M.R. Seshadri |

B.E |

Professor Emeritus |

Manufacturing |

|

7 |

Mrs. Toral AnandKumar |

M.E |

Assistant Professor |

Material Science CAD & Analysis |

|

8 |

Mr. Thameemul Ansari Ameen |

M.E |

Assistant Professor |

Thermal Science |

|

9 |

Mr. V. Arul |

M.E |

Assistant Professor |

Metrology& CAM |

|

10 |

Dr.A.Chidambaram |

M.E.,Ph.D. |

Assistant Professor |

CAD/CAM, Composites, Plastic Deformation Processes, Kinematics of Machinery |

|

11 |

Dr. T. Prabakaran |

Ph.D. |

Assistant Professor |

Thermal Engineering, Heat Engines, Manufacturing |

|

12 |

Mr. K. Rajkumar |

M.E., (Ph.D.) |

Assistant Professor |

Energy Engineering |

|

13 |

Mr. Karthik Hari D |

M.E. |

Assistant Professor |

Energy Engineering |

|

14 |

Dr.G.Vijayan |

B.E., M.E., Ph.D. |

Professor |

Solar thermal collectors, Nanofluid,Renewable energy, Heat transfer, Mass transfer |

|

15 |

Mr. Brithivi Raj. G |

M.E. |

Assistant Professor |

Manufacturing, Finite Element Analysis, Theory of machines |

|

16 |

Mr.M.Vijayananthan |

M.E. |

Assistant Professor |

Engineering Design |

|

Distinguished Alumni |

||

|

Name of the Alumni |

Year of graduation |

Current Position |

|

Abhinav Balaji |

2015 |

Technical Program Manager as, Apple USA |

|

R. Bhuvaneswaran |

2015 |

Design engineer in ASPARK, JAPAN |

|

Vignesh Subbukrishna |

2015

|

Manager, Piping Technology and products Inc, USA |

|

Shivakumar Raj |

2015 |

Industrial Engineer (Supply Chain) at Duggal Brooklyn, New York,USA |

|

Mitravarun Anand |

2015 |

Mechatronics and Robotics Engineer at Worcester Polytechnic Institute |

|

Pranav Chander Pattabiram |

2015

|

Product designer at VP Labs |

|

Jithin Chandran |

2016 |

Engineering Officer, Aeronautical Engineering (Mechanical) Branch Indian Air Force |

|

Sasank BVL |

2017 |

Manager, Reliability Engineering and Maintenance Department, Reliance Industries Limited Corporate |

|

Chakara Rajan Madhusudanan |

2017 |

Energy Services Engineer, Cedar Falls Utilities, Iowa,USA |

|

Sathish Pandian |

2018 |

Flying Officer Sathish P, Engineering Officer, Aeronautical Engineering (Mechanical) Branch Indian Air Force |

|

Entrepreneurs |

||

|

Name of the Alumni |

Year of graduation |

Company Name |

|

M. Lalit Kumar |

2017 |

SM3 QUALITY CHEMICALS |

|

Dinesh Kumar |

2018 |

TRIPLET3DZ |

|

Higher Studies |

||||

|

BATCH |

NAME |

HIGHER DEGREE |

UNIVERSITY |

YEAR OF PASSING |

|

2019 |

Kailash Krishnamoorthy |

MS program in Automotive Engineering |

Clemson University's Graduate School |

Pursuing |

|

Anerudh Vijayaraghavan |

M.S Industrial Engineering |

Pennsylvania State University |

Pursuing |

|

|

Harish Balaji Seetharaman |

M.S Sustainable Energy Systems |

University Admissions in Sweden |

Pursuing |

|

|

Prakash Sudhakar |

M.S Industrial Engineering |

Arizona State University, Tempe Campus. |

Pursuing |

|

|

2018 |

Ramkiran V |

M.S Industrial & System Engineering |

Carleton University, Canada |

Pursuing |

|

Gowtham A |

M.S industrial System |

Technical University Liberec, Czechia |

Pursuing |

|

|

Prasad S |

M.S Industrial Management |

Uppsala University, Sweden |

Pursuing |

|

|

Anirud G J |

M.S Industrial Management |

Uppsala University, Sweden |

Pursuing |

|

|

Aravind Srinivasan |

MBA |

GREAT LAKES INSTITUTE OF MANAGEMENT, Tamilnadu |

Pursuing |

|

|

Ajith |

M.E |

Anna University, Chennai |

Pursuing |

|

|

Akash Raja |

M.S |

Conestoga College Institute Of Technology And Advanced Learning |

Pursuing |

|

|

2017 |

Aashiqe Rasul |

M.Sc |

Manipal Academy of Higher Education |

Pursuing |

|

Chakararajan M |

M.S.Industrial Engineering |

CLEMSON UNIVERSITY,USA |

2019 |

|

|

Chandramoulee M |

M.S. Industial & System Engineering |

SAN JOSE STATE UNIVERSITY,CALIFORNIA |

2019 |

|

|

Ganesh |

M.E |

AMET |

Pursuing |

|

|

Mohammed Ajmal |

MBA |

MACFAST INSTITUE,KERALA |

Pursuing |

|

|

Pradiv J |

LLB |

SRM UNIVERSITY LL.B(HONOURS) |

Pursuing |

|

|

Subramanian.T |

M.S. Industial & System Engineering |

BINGHAMTON UNIVERSITY, New York |

Pursuing |

|

|

Deepak J |

M.E |

HINDUSTAN UNIVERSITY |

2019 |

|

|

2016 |

AKASH.S |

Master’s Engineering Management |

DEAKIN UNIVERSITY |

2018 |

|

KARTHICK MANIKANDAN G D |

M.S. Industial & System Engineering |

IOWA STATE UNIVERSITY |

2018 |

|

|

KARTHIKEYAN L |

M.S Industrial Engineering |

RWTH AACHEN UNIVERSITY |

2018 |

|

|

VAMSI.V |

Master’s Engineering Management |

DEAKIN UNIVERSITY |

2019 |

|

|

VANATHY VISHALI S |

Master’s Engineering Management |

DEAKIN UNIVERSITY |

2019 |

|

|

SARAVANAN.K.S |

MBA |

BHARTIYAR UNIVERSITY |

2018 |

|

|

VIGNESH N |

Master’s Engineering Management |

DEAKIN UNIVERSITY |

2018 |

|

|

VISHNU AISHWARAYAN S.M |

M.S Industrial Engineering |

WORCESTER POLYTECHNIC INSTITUTE |

2018 |

|

|

BALAJE.P |

M.E Internal Combustion Engineering |

ANNA UNIVERSITY |

2018 |

|

|

VINODH.M |

MBA |

VIT UNIVERSITY |

2018 |

|

Jithin Chandran from batch 2012-16 joins the Indian air force by clearing AFCAT and SSB interview.

P Sathish (Batch 2013-2017) have joined INDIAN AIR FORCE

Sports

Research and Consultancy

SPONSORED RESEARCH

|

Academic Year |

Project Title |

Funding Agency |

Amount |

Status |

|

2015-2016 |

15kWp Rooftop Solar Photo Voltaic Power Plant |

- |

7,12,800 (Subsidy given by TEDA) |

Functioning |

|

2018-2019 |

Molten Salt Oxidation |

Tamilnadu State Council for Science and Technology |

7,500 |

Completed |

PATENT

|

S. No |

Name of the Applicant (s) |

Name of the Inventor (s) |

Title |

Application No. & Patent Filed Date |

Current Status |

|

1 |

Vinjamoor Seshadri Raghunathan

|

Chetlapalli Venkata Sathyanarayana Raju Darbhamalla Venugopal Lokeshwaran Kandaswamy Neelam Venkata Rama Rao Putsala Raghavendra Srikanth |

Novel Process For Separation Of Gadolinium Silicon Germanium Alloy And Its Associated Fluoride Slag. |

IN 201711041922 17.11.2017 |

Registered |

|

SL.NO. |

LIST OF MOU’S |

TANGIBLE OUTCOME |

|

1 |

Easun MR Group |

Consultancy, project, industrial visit, sponsored endowment award for best students |

|

2 |

Super Auto Forge Private Limited |

Final project, industrial visit, guest lecture |

|

3 |

Sundaram Brake Linings Limited |

Final year project |

|

4 |

TVS Motor Company Limited |

Final year project, industrial visit, guest lecture |

|

5 |

Addison & Co., Limited |

Final year project |

|

6 |

Simpson & Co., Limited |

Final year project |

|

7 |

V I Micro Systems Private Limited |

Final year project Staff training |

|

8 |

Consolidated Construction Consortium Limited (CCCL) |

Placement |

|

9 |

ACEMICROMATIC CHARITABLE TRUST |

Staff training |

|

10 |

UNIVERSITI SAINS MALAYSIA |

Final year projects |

|

11 |

Rajalakshmi Engineering College |

Margdarshan |

|

12 |

Bimetal Bearings Limited |

Industrial visit |

|

13 |

Wabco India Limited |

Final year project, guest lecture |

Sponsored Project

Solar Energy Project:

MOU’s Signed for collaborative, Research and Project work with institution and organizations are,

Projects were done in various fields

Students of mechanical engineering department gain industrial exposure and are prepared to face future challenges by carrying out their Final Year Projects work in various PSU/Private sectors as per their field of interest categorized below.

Projects were undertaken in various PSU/Private Sectors: